If you have been too frequently going for Whitworth Thread Gauge and Metric Tap replacements then you will be unnecessarily disrupting the manufacturing process frequently. You will also be spending more money than you should in frequent replacement of these tools. It is therefore important to maintain these tools well to get maximum life out of these tools.

You will be able to improve the life of your Metric Tap and your thread gauges by following simple maintenance routines. We already know that thread taps are highly prone to damages. They could break any time and they could be get damaged any time. If along with it if it is also poorly maintained, you will end up running into a series of issues. It is no pleasant situation to have your thread tap break in the component. In such scenarios, it is not only the thread tap that is damaged and would need to be replaced but at times the entire component may have to be junked because of the damages that happen when removing the broken thread tap from the component. Therefore, you must avoid all possible situations that could possibly lead to damages to the thread taps.

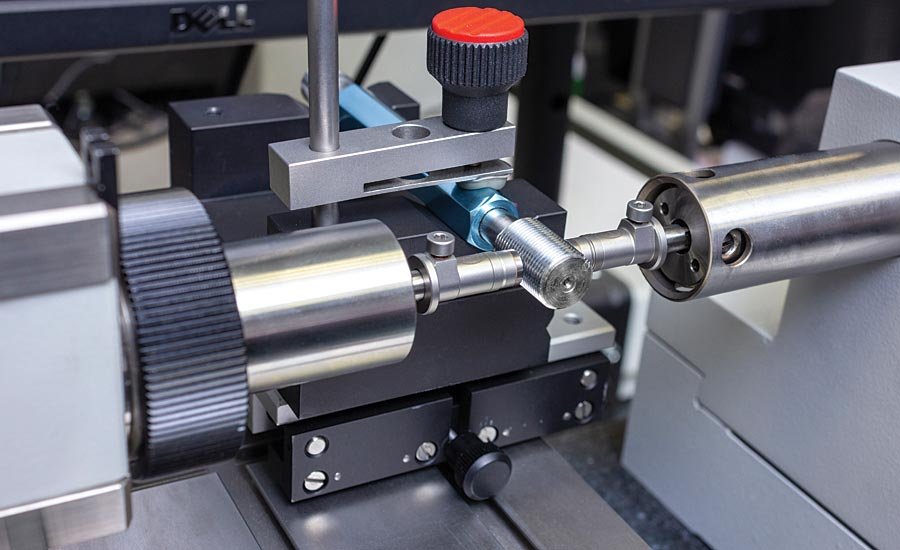

You must ensure to use the most suitable type of thread tap for the material at hand. Not all thread taps could be used on all materials. One needs to take a well-informed decision in this regard and all the technical aspects have to be taken into consideration before deciding which type of thread taps have to be used.

Correct cooling agents must be used during the thread tapping process. If you do not use approved supplies, it will result in a number of mishaps during the tapping process. If the thread tap is not going to be used for a considerable period, then it has to be removed from the machine and stored safely. This will prevent rusting and damage of the tool. Use a good protective sheath for storing your thread gauges and thread taps.

Before storing the thread taps you must clean them thoroughly. This will ensure that there are no oil deposits or there are no coolant deposits on the thread tap. Such deposits could damage the profile of the thread tap. Before using as well you must clean the thread taps so that the components will not be damaged.

It is important that you give similar care and attention to your thread gauges as well. Your thread gauges are inspection tools. They should not be handled carelessly. If these inspection tools are flawed then your measurements will be inaccurate and in other words the tool will not be able to perform its role in establishing the accuracy of the threaded components. You should not therefore underestimate the importance of thread gauge and thread tap maintenance. These tools will be able to perform their functions only when they are taken good care and when they are well-maintained.